Diaphragm Instruments

How it works

It is a fairly conventional technology, but at the same time diaphragm instruments are quite up to date in the sense that they are eco-friendly (or "flygskam-free") as they do not need electric power for operation because diaphragms undertake both roles of detecting barometric pressure and actuating the pointers.

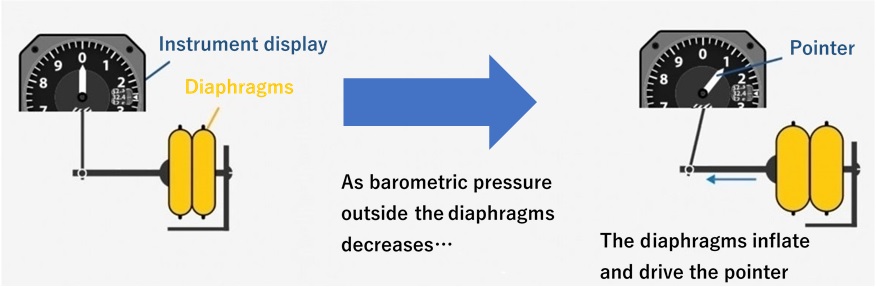

Mechanism of diaphragms driving the pointer of a barometric altimeter

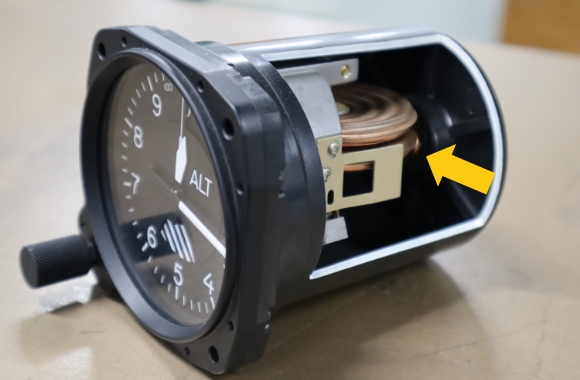

Cutaway model of barometric altimeter (diaphragms indicated with yellow arrow)

Vacuum diaphragm & open diaphragm

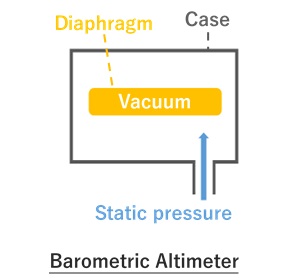

Vacuum-type diaphragms are used in barometric altimeters, which detect ambient air pressure with reference to the vacuum inside their diaphragms. The higher altitude rises, the lower the atmospheric pressure becomes, thus the pressure pushing the diaphragm from outside diminishes. So, a vacuum diaphragm inflates as the aircraft climbs, and it deflates as the aircraft descends. A barometric altimeter translates such inflation/deflation into altitude reading.

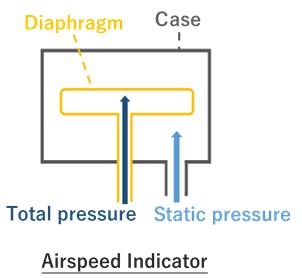

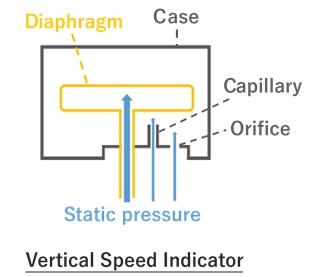

On the other hand, open-type diaphragms can be found in airspeed indicators and vertical speed indicators.

As described in "what is a Pitot tube?" of this site, airspeed is calculated from dynamic pressure of the air stream. With regard to aircraft flying or speeding on the runway, dynamic and static pressures of the airflow are in a relationship expressed in the following equation:

Dynamic pressure (i.e. pressure of the airstream flowing from fore to aft) + Static pressure (i.e. ambient atomospheric pressure) = Total pressure

A Pitot tube sends total pressure into the airspeed indicator's diaphragm, while static pressure fills up the instrument (outside of the diaphragm.) As the aircraft speeds up, dynamic pressure of the airflow increases i.e. the difference between total and static pressures increases, making the diaphragm inflate. This is how airspeed indicators measure airspeed.

As to a vertical speed indicator (also known as rate-of-climb indicator or variometer) both inside and outside of its diaphragm are filled with static pressure. Air flows into the diaphragm smoothly, though, while inlets to the outside called capillary and orifice are so narrow that flow is limited. So, when altitude either goes up or down and barometric pressure varies, the inside follows the change without delay but the outside needs some time to catch up. This lag results in a difference between pressures inside and outside of the diaphragm, making it inflate or deflate. Vertical speed indicators convert such inflation/deflation into the rate of climb, which is the rate of change in altitude per minute.

Diaphragms can be devided into two groups; vacuum type and open (or differential pressure) type. The former is kept vacuum, while outside air flows into the latter.

Vacuum-type diaphragms are used in barometric altimeters, which detect ambient air pressure with reference to the vacuum inside their diaphragms. The higher altitude rises, the lower the atomosperic pressure becomes, thus the pressure pushing the diaphragm from outside diminishes. So a vacuum diaphragm inflates as the aircraft climbs, and it deflates as the aircraft descends. A barometric altimeter translates such inflation/deflation into altitude reading.

On the other hand, open-type diaphragms can be found in airspeed indicators and vertical speed indicators.

As described in "what is a Pitot tube?" of this site, airspeed is calculated from dynamic pressure of the air stream. With regard to aircraft flying or speeding on the runway, dynamic and static pressures of the airflow are in a relationship expressed in the following equation:

Dynamic pressure (i.e. pressure of the airstream flowing from fore to aft) + Static pressure (i.e. ambient atomospheric pressure) = Total pressure

A Pitot tube sends total pressure into the airspeed indicator's diaphragm, while static pressure fills up the instrument (outside of the diaphragm.) As the aircraft speeds up, dynamic pressure of the airflow increases i.e. the difference between total and static pressures increases, making the diaphragm inflate. This is how airspeed indicators measure airspeed.

As to a vertical speed indicator (also known as rate-of-climb indicator or variometer) both inside and outside of its diaphragm are filled with static pressure. Air flows into the diaphragm smoothly, though, while inlets to the outside called capillary and orifice are so narrow that flow is limited. So when altitude either goes up or down and barometric pressure varies, the inside follows the change without delay but the outside needs some time to catch up. This lag results in a difference between pressures inside and outside of the diaphragm, making it inflate or deflate. Vertical speed indicators convert such inflation/deflation into the rate of climb, which is the rate of change in altitude per minute.

TKK's expertise

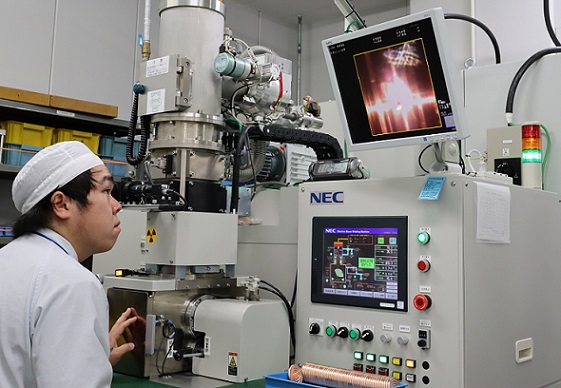

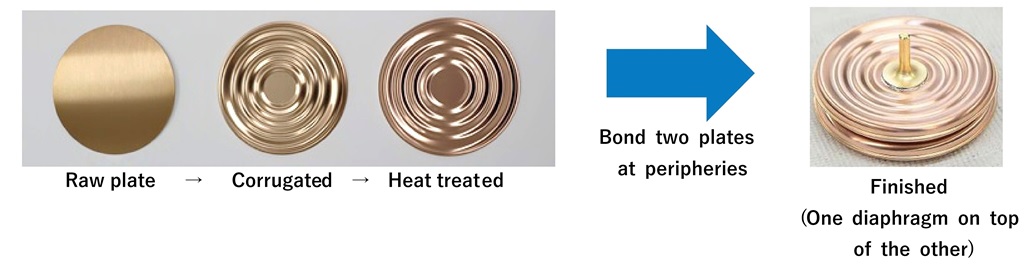

The bonding process requires particularly high skills, since the plates are as thin as 0.05mm and made of copper (which is difficult to weld) and they need to be bonded just at their peripheries. We achieve this by skillful soldering by hand as well as automated welding by a custom-made electron beam welder (EBW.)

In addition to the high energy density that is a known feature of electron beam welding, our EBW has an excellent performance to stably pinpoint its beam.

Automatic Electron Beam Welder

-